-

Home

-

Products

- Solution

- WHY JUNPU

- Services

- Resources

- News

- Contact Us

Optical splice closures are essential components in fiber optic networks, as they provide protection and organization for fiber optic splices. Here are some key points to know about optical splice closures:

Protection: Optical splice closures are designed to protect fiber optic splices from environmental factors such as moisture, dust, and debris. They provide a sealed enclosure to ensure the integrity of the spliced fibers and maintain optimal network performance.

Organization: Optical splice closures help organize and manage fiber optic splices in a neat and structured manner. They typically have trays or holders to secure and organize the spliced fibers, making it easier to access and maintain the network.

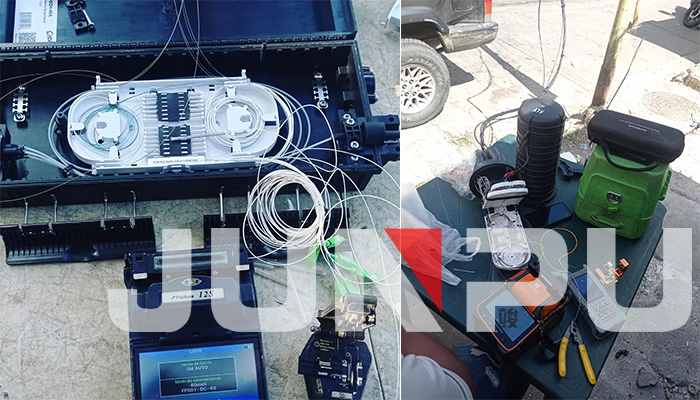

Installation: Optical splice closures are usually installed in aerial, underground, or direct burial applications. They are designed to withstand harsh environmental conditions and provide reliable protection for fiber optic splices in various installation scenarios.

Types: There are different types of optical splice closures available, including dome closures, in-line closures, and vertical closures. The choice of closure depends on the specific application requirements, such as the number of splices, installation location, and environmental conditions.

Maintenance: Regular inspection and maintenance of optical splice closures are essential to ensure the long-term performance of the fiber optic network. This includes checking for any signs of damage, ensuring proper sealing, and cleaning the closure to prevent debris buildup.

A fiber optic splice box is a device used for optical fiber connection and protection, which is usually used in indoor optical fiber wiring systems. Its main function is to connect the connectors between different optical fibers and protect the connection parts from the external environment.

The structure of the fiber optic splice box usually includes the shell, connector socket, fiber optic fixture, fiber optic protective sleeve, and other parts. The shell is usually made of high-temperature-resistant, fireproof, and corrosion-resistant materials, which can effectively protect the internal optical fiber connection part. The connector socket is used to connect the optical fiber connector to ensure the stability and reliability of the connection. The optical fiber fixture is used to fix the optical fiber to prevent the optical fiber from loosening or breaking. The optical fiber protective sleeve is used to protect the optical fiber connection part from the external environment, such as moisture, dust, etc.

In the field of communication, optical fiber is widely used in telephone networks, the Internet, cable TV and other fields. Optical fiber communication systems have the advantages of fast transmission speed, long transmission distance, and strong anti-interference ability, which can meet the growing communication needs.

In the field of data transmission, optical fiber is also widely used in data centers, computer networks and other scenarios. Optical fiber has fast transmission speed, large bandwidth, and strong anti-interference ability, which can effectively support large-scale data transmission and processing, and improve data transmission efficiency and reliability.

Fiber optic splice boxes play a vital role in protecting optical fibers and ensuring connection stability. Optical fibers are easily affected by the external environment during transmission, such as moisture, dust, etc., which can easily cause the optical fiber connection part to loosen and break, affecting the stability and reliability of data transmission. Fiber optic splice boxes can effectively protect the optical fiber connection part, prevent the optical fiber from being affected by the external environment, and ensure the stability and reliability of optical fiber transmission.

Therefore, optical fiber is increasingly used in the fields of communication and data transmission, and the role of optical fiber splice closures in protecting optical fibers and ensuring connection stability is becoming increasingly important. It can effectively protect the optical fiber connection part, ensure the stability and reliability of optical fiber transmission, and provide important guarantees for the normal operation of modern communication networks and data transmission systems.

Common types of fiber optic splice closures include heat shrink splice closures and mechanical splice closures. They have their own characteristics and applicable scenarios in protecting optical fibers and ensuring connection stability.

The heat shrink splice closure uses a heat shrink sleeve to fix and protect the optical fiber connection part, and the sleeve is tightened by heat shrink technology to form a solid protective layer.

Advantages: simple and quick installation, high connection stability, good waterproof and dustproof effect, suitable for outdoor environments or scenes requiring waterproof and dustproof.

Disadvantages: relatively high cost, requires professional equipment and technology for installation, and is not suitable for scenes with frequent disassembly.

The mechanical splice closure uses a mechanical structure to fix and protect the optical fiber connection part, usually fixed by threads or buckles.

Advantages: simple and convenient installation, suitable for scenes with frequent disassembly, and relatively low cost.

Disadvantages: relatively poor connection stability, not as good as the heat shrink splice closure in waterproof and dustproof effect, and limited applicable environment.

When choosing a suitable type of fiber optic splice box, you need to consider the specific usage scenarios and needs:

If it is in an outdoor environment or a scene that requires waterproofing and dustproof, you can choose a heat shrink splice box to ensure connection stability and protection effect.

If it is in a scene that requires frequent disassembly or cost control is more important, you can choose a mechanical splice box to meet the needs of flexibility and economy.

Selecting the right fiber splice closure is crucial to ensure the protection and stability of fiber optic connections. Here are some factors to consider when choosing a fiber splice closure:

Environment: Consider the installation environment where the fiber splice closure will be placed. If it is an outdoor installation, you will need a closure that is weatherproof, waterproof, and UV resistant. Indoor closures may have different requirements.

Capacity: Determine the number of fiber splices that the closure needs to accommodate. Choose a closure that can handle the required number of fibers, ensuring that there is enough space for future expansions.

Splice Protection: Look for a closure that provides adequate protection for fiber splices, such as mechanical protection, dustproof, and moisture resistance. This will help maintain the integrity of the fiber connections over time.

Installation Method: Consider the installation method of the closure. Some closures are designed for aerial installations, while others are suitable for buried or underground applications. Make sure to choose a closure that is compatible with the installation method you plan to use.

Ease of Access: Select a closure that allows for easy access to the fiber splices for maintenance and repairs. Look for closures with a user-friendly design that simplifies access to the internal components.

Compatibility: Ensure that the fiber splice closure is compatible with the type of fiber optic cables and connectors you are using. This includes considering the cable diameter, connector types, and compatibility with fusion splicing or mechanical splicing.

Cost: Consider the cost of the fiber splice closure and compare it with your budget. While it is important to choose a high-quality closure that meets your requirements, also consider the cost-effectiveness of the solution.

By considering these factors and evaluating your specific needs, you can select the most suitable fiber splice closure for your fiber optic network. It is recommended to consult with a professional or supplier to ensure that you choose the right closure for your installation requirements.

Call us on:

Call us on:  Email Us:

Email Us:  Wanhua Science and Technology Park, No. 528, Shunfeng Road, Donghu Street, Linping District, Hangzhou City, Zhejiang Province

Wanhua Science and Technology Park, No. 528, Shunfeng Road, Donghu Street, Linping District, Hangzhou City, Zhejiang Province