-

Home

-

Products

- Solution

- WHY JUNPU

- Services

- Resources

- News

- Contact Us

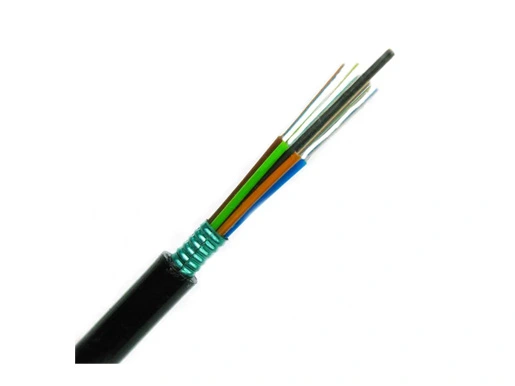

The fibers, 125μm, are positioned in a loose tube made of a high modulus plastic. The tubes are filled with a water-resistant filling compound. A steel wire, sometimes sheathed with polyethylene (PE) for cable with high fiber count, locates in the center of core as a metallic strength member. Tubes (and fillers) are stranded around the strength member into a compact and circular cable core. The PSP is longitudinally applied over the cable core, which is filled with the filling compound to protect it from water ingress. The cable is completed with a PE sheath.

| Attenuation | @850nm | ≤3.0dB/km | ≤3.0dB/km | ||

| (+20℃) | |||||

| @1300nm | ≤1.0dB/km | ≤1.0dB/km | |||

| @1310nm | ≤0.36dB/km | ≤0.36dB/km | |||

| @1550nm | ≤0.22dB/km | ≤0.23dB/km | |||

| Bandwidth | @850 | ≥500MHZ·km | ≥500MHZ·km | ||

| (Class A) | |||||

| @1300 | ≥1000MHZ·km | ≥600MHZ·km | |||

| numerical aperture | 0.200±0.015NA | 0.275±0.015NA | |||

| Optical fiber cut off wavelength | ≤1260nm | ≤1480nm |

Mainly adopted to the duct, on-messenger aerial, cable trench.

Call us on:

Call us on:  Email Us:

Email Us:  Wanhua Science and Technology Park, No. 528, Shunfeng Road, Donghu Street, Linping District, Hangzhou City, Zhejiang Province

Wanhua Science and Technology Park, No. 528, Shunfeng Road, Donghu Street, Linping District, Hangzhou City, Zhejiang Province